DRS Wheel Block System Manufacturing Process

The DRS wheel block system, typically used in crane and material handling equipment, is designed for compact design, high load capacity, and modularity. The manufacturing process involves several key stages:

DRS Wheel Block System Manufacturing Process

1. Design & Engineering

Requirements Analysis: The process begins with gathering the technical specifications and load requirements (e.g., wheel load, travel speed, environment).

3D Modeling: Engineers use CAD software (like SolidWorks or AutoCAD) to create detailed 3D models of the wheel block, including housing, wheel, shaft, and bearing arrangements.

Finite Element Analysis (FEA): Stress analysis is performed to ensure the structural integrity of the components under various loading conditions.

2. Material Selection & Procurement

Housing: Typically made from high-grade cast iron or steel, selected for strength and durability.

Wheels: Made from hardened steel or spheroidal graphite iron, often with a hardened running surface for wear resistance.

Bearings and Axles: Sourced from reliable suppliers and made of high-performance alloy steel.

Seals and Fasteners: High-quality sealing systems are chosen to protect internal components from dust, moisture, and contaminants.

3. Casting and Machining

DRS Wheel Block Housing Manufacturing Process

MAILUN has a set of strict production technology of DRS wheel block system housing, which is strictly controlled by mold making, casting, heat treatment, gold processing, rust prevention treatment, etc., to ensure the overall performance and quality of the DRS wheel block housing.

DRS Travelling Wheel Manufacturing Process

DRS Travelling Wheel Manufacturing Process

The DRS travelling wheel adopts the forging process, so as to better maintain the stability of the steel. DRS travelling wheel mechanical properties improved by a series of heat treatment, and then through multiple processing processes to complete the wheel core production. MAILUN can customize different materials according to the needs of different field images, such as pumping steel, alloy steel, etc.

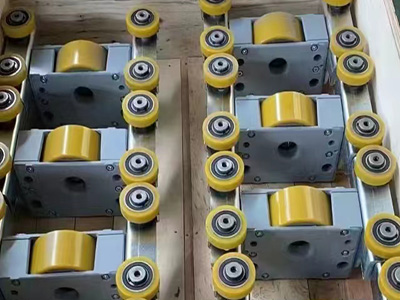

DRS Wheel Block System Assembly

DRS Wheel Block System Assembly

The DRS travelling wheel, housing and bearing will installed together.

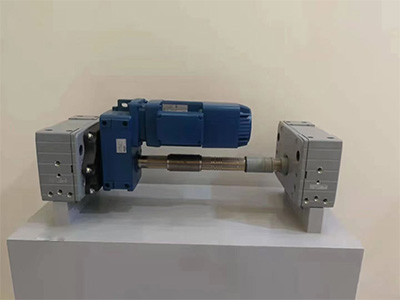

4. Assembly

DRS Wheel Block System Assembly and Debugging

According to the design requirements of working conditions, load, speed, etc., DEMAG travelling wheel block will be equipped with motor and reducer, and installation and debugging will be operated before leaving the factory.

5. Quality Control

Dimensional Inspection: Using CMMs (Coordinate Measuring Machines), micrometers, and gauges to verify critical dimensions.

Load Testing: Some manufacturers perform simulated load testing to ensure structural performance under operational loads.

Nondestructive Testing (NDT): Ultrasonic, magnetic particle, or dye penetrant testing is done on critical parts for internal flaws or surface cracks.

6. Painting and Surface Protection

Surface Preparation: Shot blasting or cleaning is performed to remove rust and impurities.

Coating: An anti-corrosion primer followed by a topcoat (often in RAL colors) is applied for long-term protection in industrial environments.

7. Packaging and Delivery

DRS Wheel Block System Inspection and Packaging before delivery

DRS Wheel Block System Inspection and Packaging before delivery

The last step before packing the DRS wheel block system, the quality inspection department conducts a series of product inspection and puts out the certificate of qualification, and packages and ships according to the requirements.

MAILUN provides professional and comprehensive pre-sales and after-sales

services to ensure that your needs and experience are met. If you need please

contact us anytime!