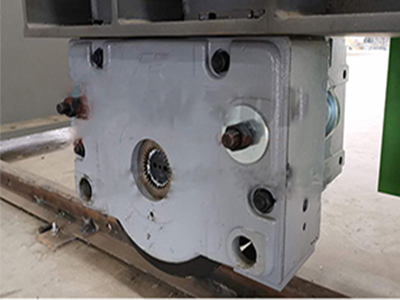

DRS Crane Travelling Wheel Block Maintenance Measures

The DRS crane travelling wheel block is a crucial component in the operation of overhead cranes, ensuring smooth and efficient movement along the runway rail. To maintain the optimal performance and extend the lifespan of this vital part, it is essential to implement a comprehensive maintenance program.

Regular inspections should be conducted to identify any signs of wear, damage, or misalignment. This includes checking the wheels for cracks, flats, or excessive wear, as well as inspecting the bearings and seals for lubrication and condition. Any identified issues should be addressed promptly to prevent further deterioration and potential failures.

Lubrication is another key aspect of maintaining the DRS crane travelling wheel block. The wheels, bearings, and other moving parts require regular lubrication to reduce friction, wear, and heat generation. It is important to use the correct type and amount of lubricant, as specified by the manufacturer, to ensure effective lubrication and prevent damage.

Additionally, the wheel block assembly should be kept clean and free of debris, which can cause premature wear and failure. Regular cleaning and inspection of the runway rail and wheel block assembly will help to identify and remove any contaminants that may affect performance.

Finally, it is important to have a well-documented maintenance schedule and to adhere to it strictly. This will ensure that all necessary inspections, lubrications, and repairs are performed in a timely and effective manner, keeping the DRS crane travelling wheel block in optimal condition and reducing the risk of unexpected failures.

In conclusion, proper maintenance of the DRS crane travelling wheel block is essential for the safe and efficient operation of overhead cranes. By implementing a comprehensive maintenance program, including regular inspections, lubrication, cleaning, and adherence to a maintenance schedule, you can ensure the long-term performance and reliability of this vital component.