KARL GEORG Wheel Blocks

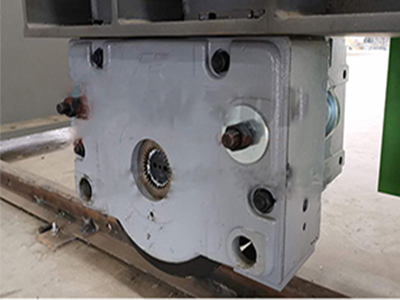

High Performance ATLAS-RB 400 Wheel Block

The ATLAS(Karl Georg) RB 400 wheel block is a high performance travelling wheel block system , which can be cast from ductile iron, stainless steel ,Vulkollan® coated , PA 12G coated and ductile iron EN-GJS-700-2 (GGG 70),designed to meet heavy duty and demanding industrial applications.

The ATLAS(Karl Georg) RB 400 wheel block is a high performance travelling wheel block system designed to meet heavy duty and demanding industrial applications. In this paper, the ATLAS RB 400 Wheel Block System will be analyzed from materials and application scenarios.

Wheel Material

The ATLAS RB 400 Wheel Block System can be cast from ductile iron, stainless steel ,Vulkollan® coated , PA 12G coated .

Ductile Iron EN-GJS-700-2 (GGG 70)

Ductile iron material with high load bearing and high wear characteristics. EN-GJS-700-2 (GGG 70) ductile iron material is the ideal material for the wheel of handling equipment. The ductile iron material retained in the cast structure allows the wheel to lubricate naturally during use, thus reducing wear between the wheel and the track.

Stainless Steel

Wheels made of stainless steel are suitable for working in all wet environments, such as sewage treatment plants, composting plants, food processing plants, chemical sites, etc.

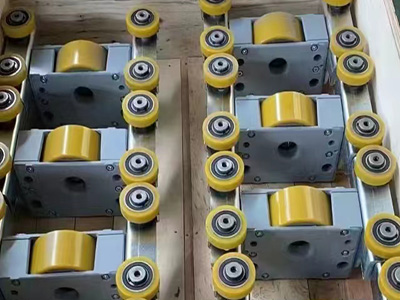

Vulkollan® Coated

The high friction coefficient of the Vulkollan® coated wheel surface allows the wheel block to operate at high acceleration. In addition, Vulkollan® coated wheels can also operate on concrete surfaces due to their high damping properties and less noise. However, compared with ductile iron wheels, the wheel pressure of coated and coated wheels is much smaller. To work in softer, wet, charged, electrostatic or explosive environments, ATLAS also offers special materials such as electrically conductive Vulkollan® polyurethane elastomers

PA 12G Polyamide Coated

PA 12G has very low moisture absorption, very high wear resistance, and very good chemical resistance. The friction coefficient of PA 12G coated rubber wheel is similar to that of ductile iron wheel. Because of its high damping characteristics, the PA 12 G polyamide coated rubber wheel has very low noise operation. Compared to ductile iron wheels, PA 12G rubber coated wheels are less loaded, but higher than Vulkollan® polyurethane rubber coated wheels. PA 12 G polyamide coated rubber wheel can work normally in the environment of minus 40 degrees Celsius to 90 degrees Celsius (instant work can withstand 120 degrees Celsius).

Usage Requirement Table

Application | Ductile ron | stainless steel | Vulkollan | PA 12 GPolyamide |

High pressure between wheel and track | + | + | - | - |

Acceleration above 0.5m/s- under gear conduction conditions | + | + | + | + |

Acceleration above 0.5m/s- under frictional conduction conditions | □ | □ | + | □ |

Run on steel | + | + | + | + |

Run on light alloys | □ | □ | + | + |

Run on concrete or uniform | - | - | + | - |

Operate in high humidity or special sanitary environment | □ | + | □ | □ |

Run outdoors in contact with snow and ice | + | + | □ | □ |

+ Suitable □Conditional fit - Not suitable

MAILUN provide you with ATLAS-RB wheel block system. The manufacturer supports customization service. The ATLAS wheel block specifications are available: 160mm, 200mm, 250mm, 315mm, 400mm, 500mm,customized travelling wheel block, and accessories such as spline shafts, wheel block shells, etc.