SEW Motors Improving Powering Precision and Efficiency

SEW motor stands out with its innovative and high-performance motors, setting new benchmarks in reliability, energy efficiency, and versatility. This article delves into the world of SEW motors, exploring their technological advancements, application versatility, and the ways in which they are revolutionizing industrial processes worldwide.

Innovative Technology at the Heart of SEW Motors

SEW-EURODRIVE has built its reputation on a commitment to excellence, continuously pushing the boundaries of what electric motor technology can achieve. Their motors are characterized by:

• High Efficiency: SEW motors are designed with energy conservation in mind. By utilizing advanced magnetic materials and optimized designs, they achieve high levels of efficiency, often exceeding IE3 standards, reducing energy consumption and operating costs over their lifetime.

• Precision Control: Equipped with state-of-the-art control systems, SEW motors offer precise speed control and dynamic response, crucial for applications requiring exact motion control, such as robotics, packaging machinery, and conveyor systems.

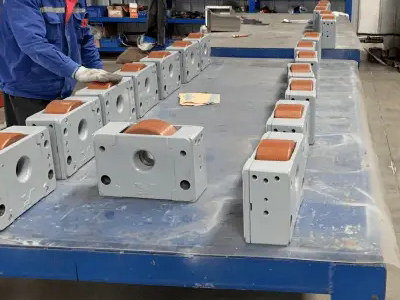

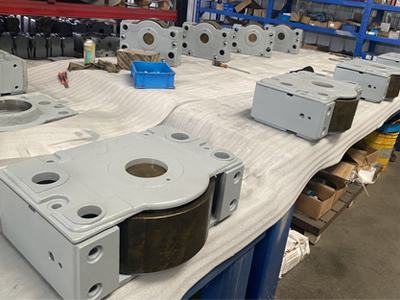

• Robustness and Durability: Built to withstand harsh industrial environments, SEW motors feature sturdy constructions with protective coatings and sealed designs, ensuring longevity even under continuous heavy-duty operation and exposure to dust, moisture, and temperature fluctuations.

• Versatility in Application: SEW offers a wide range of motors, from standard induction motors to specialized synchronous and servo motors, catering to a broad spectrum of industries and applications. Whether it's the food and beverage sector, automotive manufacturing, or heavy-duty material handling, there's a SEW motor tailored to the task.

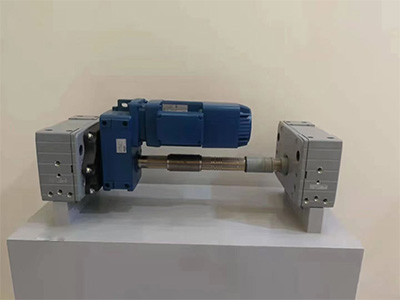

Integration with Drive Technology and Automation Systems

One of SEW's key strengths lies in its ability to provide complete drive solutions, where motors are seamlessly integrated with gearboxes, frequency inverters, and control software. This holistic approach ensures optimized system performance, simplified commissioning, and ease of maintenance. SEW's MOVITRAC and MOVIPRO frequency inverters, for example, enable precise speed and torque control, enhancing the adaptability of the motor to varying process demands.

Innovations for the Future

SEW continues to innovate, embracing Industry 4.0 principles with smart motor solutions that incorporate IoT capabilities. Their motors can be equipped with sensors and connectivity options, allowing for real-time monitoring of performance parameters, predictive maintenance, and integration into broader digital ecosystems. This level of intelligence paves the way for enhanced efficiency, reduced downtime, and future-proofed operations.

Application Examples Highlighting SEW Motor Excellence

• Automotive Manufacturing: In automotive assembly lines, SEW servo motors provide the precision and speed control necessary for intricate robotic welding, painting, and assembly tasks, ensuring high product quality and throughput.

• Material Handling: SEW’s robust induction motors power conveyors and sortation systems in distribution centers, combining high reliability with energy efficiency to handle high volumes of goods smoothly and efficiently.

• Food Processing: SEW’s hygiene-focused motors, designed for easy cleaning and resistant to washdown environments, maintain food safety standards while delivering reliable performance in harsh and wet conditions.

In conclusion, SEW motors represent the pinnacle of engineering excellence, combining power, precision, and innovation to drive industrial automation forward. With a focus on energy efficiency, versatility, and integration with cutting-edge drive technologies, SEW motors are not just components; they are integral partners in shaping the future of manufacturing and industrial processes worldwide.