DRS Crane End Carriage Wheel Manufacturer

DRS crane end carriage wheel is a travelling device used to support cranes and loads. It runs on rails to enable equipment to move on the ground. It is consists of wheels, bearings, transmission devices, motors and control systems. Among them, DRS crane end carriage wheel is a key components that directly support the weight of crane and are usually made of high-strength alloy steel or ductile iron to withstand larger loads. Bearings are used to connect the wheels and the main body of cranes to ensure that the DRS wheel block system can rotate smoothly. The transmission transmits the power of the motor to the wheels, driving the equipment to move. The control system is responsible for controlling the operation of the motor to achieve precise position control and speed adjustment.

Features

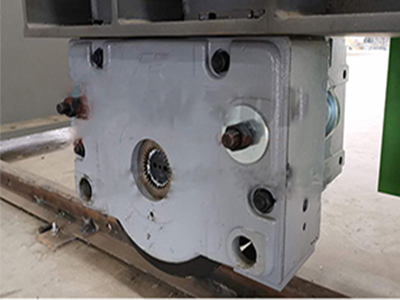

• DRS crane travelling wheels are composed of axles, bearings and wheel housings.

• Demag wheel block system is of various wheels diameters, such as 112 mm, 125mm, 160mm, 200mm, 315mm, 400mm, 500mm.

• The maximum load capacityup to (from 2.75 to 40 t)

• The DRS crane wheel block rolling surface induction hardening can reach a hardness of HB300-350 and a quenching depth of not less than 20 mm.

Application Scope

In terms of application scope, DRS Demag crane end carriage wheels are widely used in various industrial production and construction fields. In the steel, metallurgy, mining, chemical and other industries, cranes are used to hoist, transport and stack various materials and equipment. The load-bearing capacity and wear resistance of the wheels are crucial to ensure the normal operation of the crane. At the same time, in the construction field, cranes also play an important role, used for hoisting and installing various building materials and equipment. The stability and accuracy of the wheels are of great significance to ensuring construction quality and safety.