Polyurethane Traveling Wheel Block Systems

Polyurethane traveling wheel block system is soft, highly resilient, abrasion-resistant, hard, chemically resistant, low rolling resistance, and durable. Travel wheel block systems play an important role in the manufacturing industry. Almost every manufacturing industry needs to transport, merge, transfer, distribute or assemble raw materials, semi-finished products and finished products. In many applications, special operating conditions and functional requirements have to be taken into consideration.

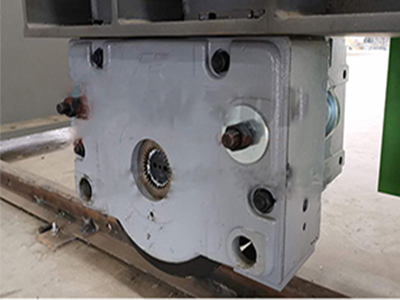

Modular wheel block system provides optimum performance ratios for a maximum load capacity (from 2.75 to 40 t) with compact dimensions. Finely graded sizes ensure that the right unit is selected for the corresponding application.Besides a wide variety of travel wheel types from the standard range, special designs are also available to meet customer requirements.

Wheel Blocking System Features

DRS 112-500 can be used for wheel loads from 2.75 t to 40 t

•Flexible

Different configurations for connecting as per clients' request

• Reliable

High quality drives for every situation

• Your choice

On request, drives equipped with VFD frequency inverter

•Maintenance-friendly

Every components can simply be pulled out from the front of the block

• Field-proven

Series components ensure maximum performance

•Compact

With space-saving pancake gear on request

•Easy installation

All components are perfectly matched and pre-assembled ready for fitting.

•Precision and durable design

Position tolerances and correspondingly precise geometries in all planes ensure that the wheel can be easily mounted on your setup, with track-gentle starting and braking characteristics.

In addition, special reinforcement ribs guarantee high rigidity.

8 Wheel Types

• Travel wheels guided by flanges on both sides, with generous wear reserves for common rail systems or with a tread to your specifications.

• Travel wheels without flanges, if required with guide rollers for rigidly guided systems.

• Travel wheels guided by a flange on one side for units running at floor level, also with a central flange for special requirements

• Large diameter travel wheels without a flange for increased ground clearance. Travel wheels for guided applications in vertical and horizontal planes of prismatic or trapezoidal design or with a concave tread.

• Flangeless travel wheels with a Hydropur tyre for high acceleration and smooth operation.

• Polyurethane travel wheels without a flange for quiet running and gentle on the runway.

• Spheroidal-graphite cast-iron wheels with a convex tread or of hardened design can also be supplied.

4 Connection Methods

• Top connection

• Pin connection

• Side connection

• End connection

Wheel Materials

• Spheroidal-graphite cast iron

• Polyurethane

• Hydropur tyres

• PEEK

MAILUN POLYURETHANE provides industrial wheel blocks for Crane Systems, Hoists, Monorail Systems, Conveyors, Heavy Loadings, Automated Guided Vehicles (AGVs), etc. If you have customized needs, please feel free to contact us