Demag Wheel Block Meets Modularity

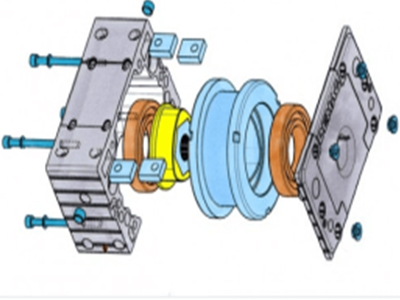

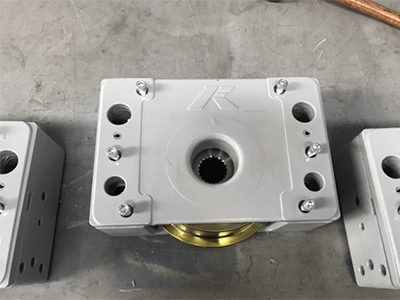

DRS travelling wheel block is mainly composed of travelling wheel, bearing seat, transmission gear, drive shaft, brake, lubrication system and so on.

DRS travelling wheel structure is as follows:

Travelling wheel: The part that directly supports the load of the crane, usually using a double rim design, with a larger contact area and a higher carrying capacity.

Bearing seat: an important part connecting the travelling wheel and the equipment body, which can adapt to the displacement and deformation under different working conditions.

Transmission gear and drive shaft: key components that transmit power to the travelling wheel.

Brake: Stopping the rotation of the DRS wheel when needed.

Lubrication system: The DRS wheel block system is lubricated to reduce friction and wear.

Fully enclosed design: The DRS travelling wheel block adopts a fully enclosed design, making it free from interference from external equipment and environment to ensure its performance. Different types of wheel boxes use different materials of the box structure, such as DRS120-DRS200 models with high strength, corrosion resistant die-cast aluminum block structure, and DRS250 and higher specifications of the model using high tensile ductile iron block structure.

DRS Demag Travelling Wheel Block Daily Maintenance

In order to ensure the performance and life of the travelling wheel block, it is necessary to maintain and maintain the components, including regularly checking the wear of the bearing seat, transmission gear and drive shaft, and timely replacing the parts with serious wear;

Lubricate the wheel regularly to reduce friction and wear;

Check the performance of the brake regularly to ensure that it can effectively stop the rotation of the traveling wheel when needed