Case

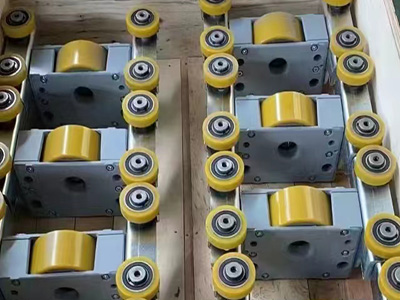

Direct Integrated Motor on the Demag Wheel Design

The direct integrated motor design on the Demag wheel is is an innovative and efficient mechanical transmission solution, which is widely used in automation equipment, logistics trucks, service robots and other fields. This design offers a number of significant advantages.

The direct integrated motor design on the Demag wheel is is an innovative and efficient mechanical transmission solution, which is widely used in automation equipment, logistics trucks, service robots and other fields. This design offers a number of significant advantages.

Spatial Optimization and Integration Improvement

The installation of the motor directly in or next to the Demag travelling wheel block greatly reduces the space occupied by traditional transmission systems (e.g. chains, belts, gearboxes), making the overall structure of the equipment more compact, which is particularly important for space-constrained applications, such as automated storage systems in narrow alleys.

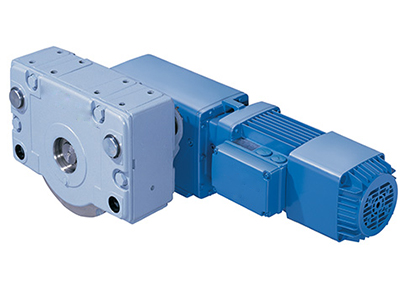

Improve Efficiency and Reduce Energy Consumption

The motor is directly installed on the DRS drive wheel to reduce the intermediate transmission link, lower the energy loss in the transmission process, and improve the overall energy efficiency of the system. This means that under the same energy consumption, the equipment can provide longer running time or greater load capacity, which is of great significance for modern industry in the pursuit of low-carbon environmental protection and operating cost control.

Precise Control and Dynamic Response

The direct coupling between the motor and the wheel shortens the control response path and improves the precision and response speed of the control system. In applications that require precise position control and dynamic speed adjustment, such as automated guided vehicles (AGVs) and robots, this design enables faster acceleration, deceleration and more precise positioning, increasing operational efficiency and flexibility.

Easy Maintenance and Enhanced Reliability

The integrated design reduces exposed transmission components, reduces the probability of failure due to wear and breakage, and simplifies routine maintenance and troubleshooting. The enclosed motor wheel block design also helps to prevent dust and water, extend service life, reduce downtime, and further improve equipment reliability and availability.

Customization and Flexibility Directly Integrate

The motor on the Demag wheel block can be customized according to different application requirements, such as adjusting the power, torque, speed and other parameters of the motor to adapt to different loads, speeds and operating environments. This flexibility enables the device design to be closer to the actual use scenario and meet the diverse application requirements.

Reduce Noise and Vibration

Direct drive wheel blocks generate less noise and vibration during operation than conventional drive systems, providing an ideal solution for applications that require a quiet operating environment, such as medical devices, library robots, and more.

The design of the integrated motor on the wheel block is a great progress in modern automation technology, which not only improves the performance and efficiency of the equipment, but also simplifies the system design, reduces the maintenance cost, and lays a solid foundation for achieving a more efficient and flexible automated working environment.

As a manufacturer integrating production and sales, MAILUN is committed to providing you with high quality motor and DRS wheel block products. If you need to purchase or replace the product, free to contact us.