Case

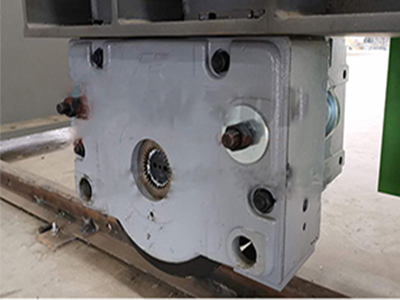

Demag DRS-125-MA35-A-60-K-H-X Crane Wheel Block

Demag DRS-125-MA35-A-60-K-H-X crane wheel block is a travel wheel set for load-bearing transportation in the Demag wheel range.

Demag DRS-125-MA35-A-60-K-H-X crane wheel block is a travel wheel set for load-bearing transportation in the Demag wheel range. The following will introduce the parameters, advantages and applications of Demag DRS-125-MA35-A-60-K-H-X in detail.

Parameters of Demag DRS-125-MA35-A-60-K-H-X travel wheel

• Drive wheel block with a shaft diameter of 35mm

With a 35mm shaft profile, it has high torsional strength and ensures smooth power transmission and alignment in the drive crane system. Ideal for applications that require precise speed control and load positioning.

• GJS (GGG) material with double-sided flange

Made of ductile iron (GJS/GGG), it has excellent wear resistance and mechanical stability. The double-sided flange prevents lateral derailment and enhances the safety of high-speed or heavy-load operations.

• 60mm tread width

The optimized 60mm tread evenly distributes loads, reduces rail wear and extends the life of the wheel and rail system.

• Horizontal guide wheels (standard)

The integrated horizontal guide wheels ensure smooth operation of the crane rails, minimizing friction and vibration.

• Top connection design

The simplified top connection facilitates installation and maintenance, and is compatible with standard crane mounting systems.

• No gearbox required

The direct drive design eliminates the need for complex gear systems, reducing maintenance costs and downtime.

Benefits of using the Demag DRS-125-MA35-A-60-K-H-X in crane system

• Enhanced load capacity: supports heavy-duty applications with dynamic loads up to 5 t.

• Lifetime in harsh environments: GJS materials are resistant to corrosion, wear and thermal stress, making them ideal for foundries or outdoor ports.

• Precision movement: The drive design ensures accurate positioning, which is critical for automated production lines or sensitive cargo handling.

• Reduced operating costs: Low-maintenance structure and durable components minimize replacement frequency and downtime.

• Safety compliance: Double flanges and guide rollers prevent derailment and comply with ISO 12488 and FEM 1.001 safety standards.

• Easy installation and low maintenance

Applications: Ideal for these crane types

• Overhead cranes (EOT cranes)

Used in factories and warehouses for lifting and transporting heavy loads over long spans. The DRS-125-MA35-A-60-K-H-X ensures a smooth ride on runway beams, even at maximum capacity.

• Gantry cranes

Deployed in shipyards and container terminals for outdoor heavy lifting. Resists weather-related wear and maintains stability on uneven tracks.

• Ladle handling cranes

Essential when transporting molten metal in steel mills. Heat-resistant GJS materials withstand the radiant heat of the ladles. Operating temperature -25°C to +150°C

• Automated Storage/Retrieval Systems (AS/RS)

Ensure precise movements in high-bay warehouses with minimal positioning errors.

Why choose DRS wheel block system ?

Demag DRS wheel block system combines decades of engineering expertise and cutting-edge material science. Its modular design ensures compatibility with existing crane systems, while its rugged construction guarantees reliability in the most challenging environments.

Contact MAILUN today to optimize your crane performance with this industry-leading wheel solution!