DRS Wheel Block System

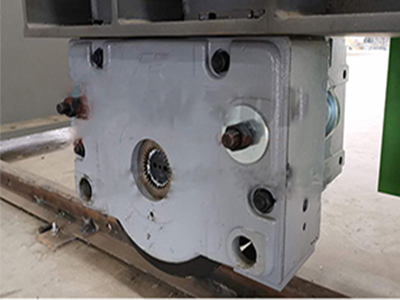

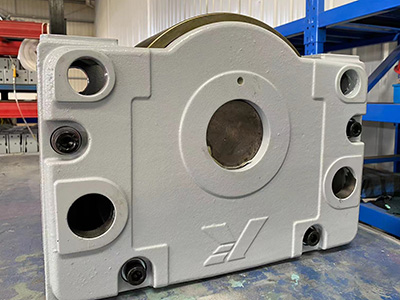

Demag DRS 125 Travel Wheel Block System

Demag DRS 125 travel wheel block system weighs 9.9kg and can bear 5t. It is used to support the load of heavy equipment such as cranes or stackers, so that it can run repeatedly on the track or rail.

Demag DRS 125 travel wheel block system weighs 9.9kg and can bear 5t. It is used to support the load of heavy equipment such as cranes or stackers, so that it can run repeatedly on the track or rail. It mainly consists of wheel and wheel box, bearing and shaft, etc.

Demag DRS 125 Wheel block manufacturing process

• Material selection: Use high-strength spheroidal-graphite cast iron (GGG 70) or steel or alloy to ensure the durability and load-bearing capacity of the wheel blcok.

• Casting or forging: The preliminary shape of the wheel block is formed through a casting or forging process to obtain a blank of the required material.

• Machining: Perform precision machining including turning, milling and drilling to ensure dimensional accuracy and surface finish.

• Heat treatment: Apply heat treatment processes, such as quenching and tempering, to improve the hardness and wear resistance of the wheel block material.

• Quality Inspection: Strict quality control is carried out at all stages of production to ensure that products comply with design specifications.

• Surface treatment: Cleaning, painting, and anti-corrosion treatment are performed to improve the corrosion resistance and aesthetics of the wheel box.

• Assembly: Assemble the processed wheel block with bearings, seals, and other components to complete the final assembly of the traveling wheel block.

• Performance testing: Perform performance testing on the assembled traveling wheel box to ensure that it meets work requirements and safety standards.

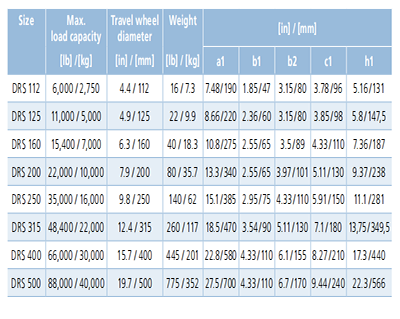

DRS 125 wheel set is one of Demag's models. MAILUN produces matching DRS wheel range, subdivided specifications include DRS 112, DRS 160, DRS 200, DRS 250, DRS 315, DRS 400, DRS 500, DRS 500, 2.75 t to 40 t of single wheel load capacity makes it the most suitable wheel set for various applications. The wide range of models of DRS wheel sets and the special wheel set system design makes it adaptable to almost any walking track and operating conditions. The DRS 125 wheel set system is cost-effective and can be installed directly.

MAILUN DRS wheel block manufacturer has precision processing equipment and professional and experienced design engineers. Please feel free to contact us for wheel consultation.