DRS Wheel Block System

Demag DRS Wheel Block Component Structure

Demag RS wheel blocks are welded from steel sheets and are suitable for applications such as impact loads. The RS system is also suitable for high temperatures (up to 250 °C) or where a stainless stee

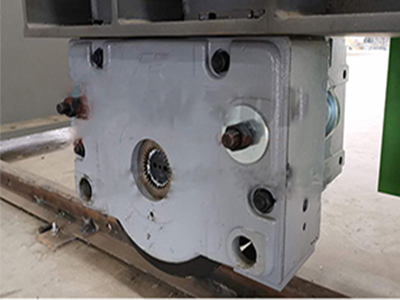

Demag DRS wheel blocks are welded from steel sheets and are suitable for applications such as impact loads. The DRS system is also suitable for high temperatures (up to 250 °C) or where a stainless steel housing is required. The system is ideal for universal applications due to its various wheel designs and the possibility of connection to the superstructure.

Dominant Component

5 sizes with load capacities ranging from 3.5 to 18 tons

Housing made of steel or stainless steel

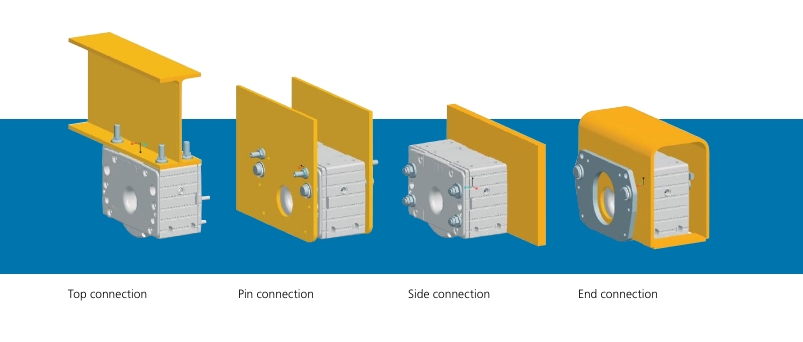

4 options for attachment to superstructure

Driven by Demag parallel shaft geared motors, equipped with modular mounting accessories such as torque brackets, guide wheels and buffers.

High Performance for Industrial Occasions

Steel and mechanical components for a long service life

Special design for high temperature applications up to 150°C or equipped with high temperature resistant bracket bearings, which can withstand high temperatures up to 250 °C

Stainless steel design is particularly suitable for the chemical, food industry and corrosive environments (specification DRS 125)

Multifunction

Wide range of standard travel wheel designs.

Housing made of steel or stainless steel

5 sizes, deadweight range from 3.5 to 18 tons (RS 125 to RS 400)

Drive Equipement

The strong connection with the hollow shaft of the gearbox (involute spline type) ensures reliable driving torque, especially suitable for forward and reverse steering situations common in walking applications.

The Demag modular system includes the D1 torque bracket (mounted directly to the wheel block) or the D2 torque bracket (mounted to the customer's super structure) to adapt the drive torque transmission.