European Travelling Wheel Block Properity

In the field of modern mechanical engineering, heavy handling application is a crucial link. The European DRS travelling wheel block, as a multi-purpose walking wheel with good prosperity, has become an important support in the field with its unique design and excellent performance. Next, we will delve into the characteristics, application fields and value of European wheel block in mechanical engineering.

The Characteristics of European Travelling Wheel Block

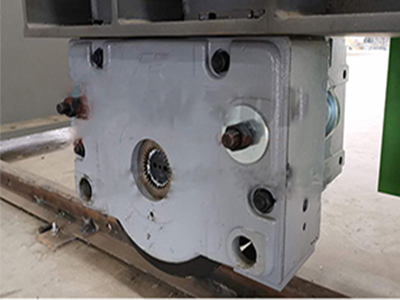

Flexible Modular Design

European travelling wheel block adopts advanced modular design concept, clients can flexibly configure and combine the travelling wheel block according to actual needs. This design allows the wheel block to adapt to a variety of different working scenarios and equipment requirements, providing users with a highly customized solution.

Accurate Size Control

The precise size is a major feature of the European wheel block. Through high-precision processing technology, to ensure that the traveling wheel block and the equipment can achieve close connection, so as to effectively reduce the size error caused by the operation of instability, excessive noise and other problems.

Smooth Operation Performance

The European wheel has been carefully designed and strictly tested, and its internal structure is reasonable and the transmission system is stable. In heavy handling applications, whether it is straight walking, turning or climbing, smooth and smooth operation can be achieved.

Various wheel Spec

In order to meet the needs of different working conditions, European travelling wheel provides a variety of specifications of travelling wheels, such as double rim, single rim, no rim, rubber wheel and so on. Different specifications of travelling wheels have different characteristics and scope of application, and clients can choose according to specific working conditions.

European Wheel Block Application Field

European wheel blocks are widely used in various cranes, such as gantry cranes, bridge cranes and so on. Its reliable power transmission and stable walking performance provide strong support for the efficient operation of the crane. In the process of lifting, moving and placing heavy objects, the walking wheel block can accurately control the walking speed and direction to ensure the accuracy and safety of the operation.

In the port loading and unloading operation, the gantry crane adopts the European walking wheel block, which can quickly and accurately lift the cargo, greatly improving the loading and unloading efficiency of the port.

Stackers Field

In the field of stackers, European wheel blocks also play an important role. Whether it is a fixed stacker or a mobile stacker, the appropriate European walking wheel block can be selected according to the actual needs. Its flexible installation mode and diversified choice of walking wheels can meet the work needs of stackers in different warehouse environments and cargo storage requirements.

In the automated three-dimensional warehouse, the mobile stacker with the European travelling wheel block can shuttle freely in a small space to achieve rapid access to goods.

Mechanical Engineering Solutions

In addition to cranes and stackers, European wheel blocks are also widely used in other mechanical engineering solutions, such as conveyors, loading and unloading equipment. Its versatility and reliability make it an important element in optimizing the performance of mechanical engineering systems.

In the conveyor line of a food processing enterprise, the conveyor using European travelling wheel block runs smoothly, can accurately transport food raw materials to various processing links, and improve the automation level of production and production efficiency.

European wheel block with its modular design, accurate size, smooth operation, multi-specification wheel and easy maintenance characteristics, in the field of mechanical engineering has shown a strong competitiveness and a wide range of application prospects. It plays an indispensable role in improving production efficiency, ensuring operation safety, and optimizing equipment performance.