DRS Wheel Block Technical Requirements for Cranes

Introduction

In the realm of industrial material handling, the efficiency and reliability of cranes are paramount. A crucial component in ensuring this performance is the DRS travelling wheel blocks, specifically designed by Demag, a leading manufacturer in the field of crane technology. Understanding the technical requirements of these wheel blocks is essential for optimizing crane operations and maintaining safety standards in demanding industrial environments. This article delves into the key aspects that define the DRS travelling wheel blocks and how they contribute to superior crane performance.

Load Capacity: The Foundation of Design

DRS travelling wheel blocks are engineered to handle specific load capacities, a fundamental consideration in crane design. These capacities are determined based on the maximum load that the crane is expected to lift or transport. Accurate load assessment ensures that the wheel blocks can withstand the stresses imposed during operation without failure, maintaining the structural integrity of the crane.

Speed and Acceleration: Enhancing Operational Efficiency

The capability of DRS wheel blocks to achieve desired speeds and accelerations is crucial for operational efficiency. These characteristics are directly linked to the crane's responsiveness and the overall productivity of the material handling process. Wheel blocks that can manage high speeds and rapid acceleration without compromising durability or safety are essential for modern industrial settings.

Track Compatibility: Ensuring Smooth Movement

The compatibility of wheel blocks with the track profile is a critical factor. The DRS wheel blocks are meticulously designed to align perfectly with the track width and curvature, ensuring smooth and steady movement. This compatibility is crucial for minimizing wear and tear on the wheels and the track, thereby extending the service life of the crane.

Alignment and Adjustment: Quick and Easy Maintenance

One of the innovative features of DRS wheel blocks is the ease of replacement and adjustment. This is facilitated by an innovative installation connection that allows for swift replacement without extensive realignment efforts. This feature significantly reduces downtime and maintenance costs, contributing to enhanced operational efficiency.

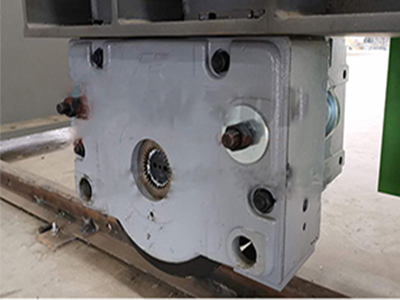

Bearings: The Core of Rotation

High-quality bearings are at the heart of DRS wheel blocks, ensuring smooth rotation and minimizing friction. These bearings are designed to withstand the rigors of continuous operation, contributing to the longevity of the wheel blocks. Regular maintenance and proper lubrication practices are recommended to keep the bearings in optimal condition.

Material and Coating: Durability and Performance

The wheel blocks are typically made of hardened steel to ensure durability and wear resistance. Additional coatings, such as polyurethane (PU), are applied to further enhance traction and reduce noise during operation. These coatings also help in mitigating wear caused by abrasive materials, ensuring consistent performance over time.

Sealing and Protection: Safeguarding Internal Components

Effective sealing mechanisms are incorporated into the design of DRS wheel blocks to protect internal components from dust, moisture, and other contaminants. This protection is vital for maintaining the integrity of the wheel blocks and prolonging their service life.

Safety and Compliance: Meeting Industry Standards

Safety is a top priority in the design of DRS wheel blocks. These components must adhere to stringent safety standards and regulations concerning load ratings, material quality, and manufacturing processes. Compliance ensures that the wheel blocks are suitable for use in various industrial settings without posing risks to operators or the facility.

Environmental Resistance: Adapting to Harsh Conditions

DRS wheel blocks are engineered to withstand exposure to a range of environmental conditions, including extreme temperatures, humidity, and corrosive substances. This resilience is crucial for ensuring continuous operation in diverse industrial environments without performance degradation.

Service and Maintenance: Accessibility and Ease

Accessibility features in the design of DRS wheel blocks facilitate regular inspections and maintenance procedures. Easy access to critical components ensures that maintenance activities can be carried out promptly and efficiently, minimizing operational disruptions.

Conclusion

Understanding and adhering to the technical requirements of DRS travelling wheel blocks is crucial for optimizing crane performance and ensuring safety in industrial operations. These components play a pivotal role in the efficiency and longevity of cranes, making them indispensable for material handling tasks in various sectors. By selecting and maintaining wheel blocks that meet these requirements, industries can significantly enhance their operational capabilities and maintain high standards of safety and performance.