Case

The Application of Demag Wheel Block on RGV

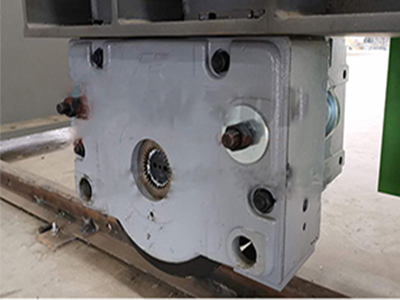

Demag wheel block systems, including the DRS and DRS-M series, are designed to provide reliable and versatile solutions for a wide range of RGV applications

Demag wheel block systems, including the DRS and DRS-M series, are designed to provide reliable and versatile solutions for a wide range of applications, including Rubber Tired Gantry Cranes (RGVs) used in automated warehouses and material handling systems.

Here's how Demag wheel blocks can be applied to RGVs:

• Modular Design: Demag wheel blocks offer a modular system that can be tailored to the specific requirements of RGVs, ensuring optimal performance for the intended load capacities and travel conditions.

• High Load Capacity: With sizes ranging from DRS-M 112 to DRS 500, Demag travelling blocks can handle load capacities from 2.75 to 40 tonnes, suitable for the heavy loads often moved by RGVs.

• Versatile Travel Wheels: The system includes a variety of travel wheel types and designs, allowing for customization to suit different track materials and surface conditions found in automated warehouse environments.

• Easy Integration: Demag wheel blocks can be seamlessly integrated into Demag's modular drive systems, providing a complete solution for RGVs, including drives, motors, and frequency inverters for smooth and precise operation.

• Low Maintenance: The wheel blocks are designed for minimum maintenance requirements, reducing downtime and operational costs, which is critical for the continuous operation of RGVs.

• High Ground Clearance: Demag wheel block system feature high ground clearance, which is beneficial for RGVs that may need to traverse uneven surfaces or obstacles in their path.

• Protection and Rigidity: The housing of the wheel blocks is designed to protect the travel wheels and bearings from external mechanical influences, ensuring high rigidity and reliable operation.

• Laser Alignment System: Demag offers a laser alignment system that can be used to ensure precise alignment of wheel blocks on multiple travel units, which is crucial for maintaining the accuracy and efficiency of RGV operations.

• Direct Connection of Accessories: Optional accessories such as guide rollers or rail sweepers can be directly connected to the wheel blocks, enhancing the functionality of RGVs in complex warehouse layouts.

• Fixed Alignment Element: The innovative installation connection of DRS-M wheel blocks allows for quick replacement without the need for readjustment, ensuring that the wheel block remains precisely positioned even after replacement.

In summary, Demag wheel block systems offer a high-performance, adaptable, and reliable solution for RGV applications, contributing to the efficiency and reliability of automated material handling systems in warehouses and distribution centers.