DRS Wheel Block System

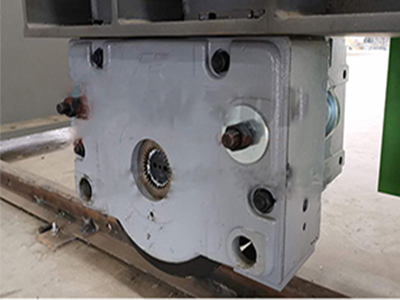

Stacker Drive Wheel Block System

The stacker drive wheel block is a key component in the stacker's travel system, responsible for driving and guiding the equipment to move smoothly on the track.

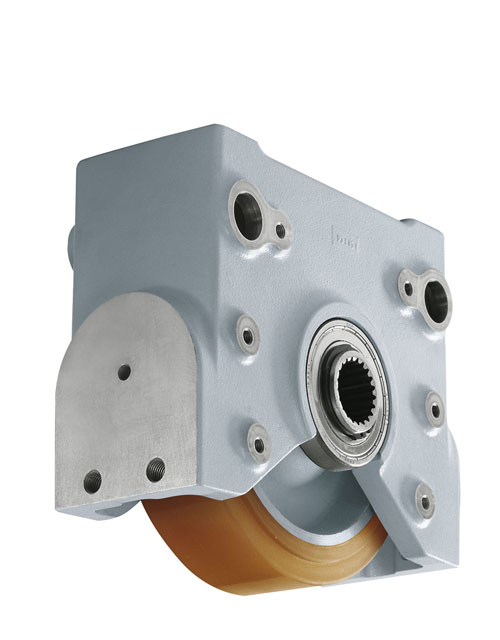

The stacker drive wheel block is a key component in the stacker travel system, responsible for driving and guiding the equipment to move smoothly on the track. It is usually composed of a high-strength metal shell, drive wheels, bearings and sealing systems, combining power transmission and durability functions. The drive wheels in the travel wheel block are powered by a motor and gear system to achieve precise positioning and efficient operation of the stacker. Its design focuses on load-bearing capacity, smooth operation and wear resistance, and is widely used in high-demand environments such as logistics warehousing and automated production lines, providing reliable guarantees for improving equipment efficiency and service life.

Basic production process of stacker drive wheel block

● Design and material preparation: Design the structure and specifications of the travel wheel block according to customer needs and application scenarios.

● Casting and processing: Cast or forge metal materials to make the main shell and internal parts of the wheel box.

● Drive wheel manufacturing: Make the drive wheel, usually including the processing of the metal inner core and the polyurethane coating process.

● Assembly and debugging: Assemble the shell, drive wheel, bearings, seals, gears and other components of the travel wheel block according to the design requirements.

● Surface treatment: Anti-corrosion treatment is applied to the outer shell, such as spraying anti-rust paint or anodizing treatment, to improve corrosion resistance.

● Quality inspection: Through load testing, walking stability testing and durability experiments, verify whether the performance and quality of the product meet the design standards.

Features of stacker drive wheel block

● Made of high-strength materials, it can withstand the large load during the operation of the stacker, ensuring the stability and reliability of the equipment.

● Equipped with high-precision bearings and drive systems to ensure the smooth operation and precise positioning of the stacker.

● Optimized gear transmission and polyurethane drive wheel design reduce operating noise while reducing vibration for smooth operation.

● Suitable for various types of stackers, including automated warehousing equipment and high-density shelf systems, to meet the diverse needs of the logistics and warehousing industry.

● The parts are highly versatile, easy to disassemble, replace and maintain, reducing the maintenance cost and downtime of the equipment.

As a professional wheel block system manufacturer, MAILUN POLYURETHANE is committed to providing high-quality and durable wheel block system solutions to global customers. Our products are based on high-quality polyurethane materials and advanced manufacturing processes. They have high load-bearing capacity, excellent wear resistance and excellent corrosion resistance, and are suitable for various stackers and automated warehousing equipment. Contact us for free customized solutions!