DRS Wheel Block System

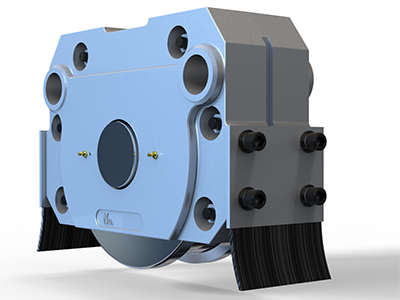

DRS travel wheel system in Heavy Load Cleanroom Crane

DRS travel wheel system in Heavy Load Cleanroom Crane is mainly responsible for supporting and guiding the crane to walk smoothly on the track.

DRS travel wheel system in Heavy Load Cleanroom Crane is mainly responsible for supporting and guiding the crane to walk smoothly on the track. Its function is not only to ensure the stability and safety of the crane, but also to reduce vibration and noise, and ensure the cleanliness requirements of the cleanroom environment. Through high-precision design and sealing technology, the wheel block can prevent pollutants from entering, maintain the cleanliness of the cleanroom environment, extend the service life of the equipment, and reduce maintenance costs.

Wheel Blocking System Features

Anti-Corrosion Materials

Some cleanroom environments may involve corrosive gases or chemicals (such as certain gases in semiconductor production, chemical raw materials in pharmaceutical production, etc.), so the wheel block of a clean room crane is usually made of corrosion-resistant materials, such as stainless steel or surface-treated alloy materials. These materials can effectively resist corrosion in the environment, ensure the long-term stable operation of DRS driving wheel block, and reduce failures and maintenance requirements caused by corrosion.

Low Maintenance Requirements

Since the cleanroom environment has strict requirements for the maintenance and cleaning of equipment, modular wheel block of a cleanroom crane is usually designed as a low-maintenance, easy-to-clean structure. Use durable and low-friction materials to reduce the maintenance workload caused by frequent wear. The shape and structure of the wheel block should also be considered during the design to ensure that it can be cleaned quickly to avoid dust accumulation and pollution.

Precision Manufacturing and High Load Capacity

Equipment in cleanrooms often requires precise operation. As a key component of crane movement, traveling wheel block system needs to have a high-precision manufacturing process to ensure accuracy during operation. The bearings, gears and other components in the wheel blocks are usually precision machined to maintain a small tolerance range to ensure accurate and reliable operation in harsh environments. In addition, the wheel block design of the cleanroom crane also needs to be able to bear the weight of the crane and its load to ensure stability under high-load working conditions. Drives wheel block system with different load-bearing capacity can be designed according to your requirements.

Antistatic Performance

Static electricity is a potential risk factor in some cleanroom environments, especially in industries such as semiconductor manufacturing. The accumulation of static electricity may damage sensitive electronic components or cause fire hazards. Therefore, the wheel block of the cleanroom crane often adopts an antistatic design. The material and coating of the wheel block usually adopt antistatic materials, or built-in static elimination devices to ensure that static electricity does not accumulate during the movement of the crane, thereby avoiding potential harm to the cleanroom environment and production process.

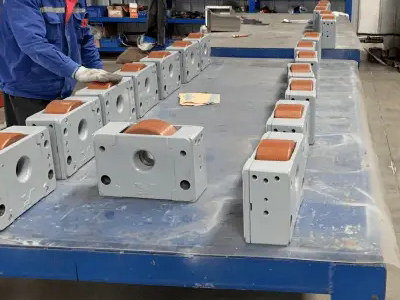

MAILUN is a manufacturer that focuses on designing and manufacturing wheel blocks. We can manufacture wheel blocks with different installation types according to your needs, including top installation, bottom installation, side installation, with tracks, without tracks, polyurethane materials, stainless steel materials, PEEK, polymer. You can directly provide drawings, or tell usyour demands, and we will help you design. We hope to hear from you.