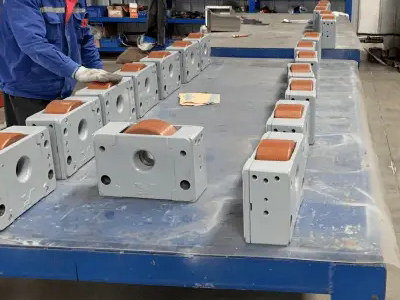

DRS Wheel Block System

Custom DEMAG Heavy Duty Wheel Block System for Stackers

The DEMAG Heavy Duty Wheel Block System for stackers is an advanced mechanical solution designed to enhance the mobility and stability of stackers in various industrial environments.

The DEMAG Heavy Duty Wheel Block System for stackers is an advanced mechanical solution designed to enhance the mobility and stability of stackers in various industrial environments. Stackers, commonly used for handling heavy materials in warehouses, ports, and logistics hubs, rely on robust wheel systems to ensure safe and efficient movement.

The DEMAG system is engineered to meet the demanding requirements of industries that deal with high load capacities, frequent operation, and harsh working conditions. This system provides enhanced durability, smoother operation, and precise control, ensuring that stackers can perform their material handling tasks with increased productivity and safety.

At the core of the DEMAG Heavy Loading Wheel Blocking System is its custom-designed travel wheel, which is crucial for ensuring smooth, controlled movement of the stacker across various surfaces. The wheel block system integrates seamlessly into the stacker's chassis, providing reliable support even under high-stress conditions. The travel wheel is made from high-quality materials such as reinforced steel or durable composite alloys, designed to withstand extreme wear and tear. These materials are selected not only for their strength but also for their ability to resist corrosion and maintain functionality in challenging environments, including dusty, wet, and abrasive conditions. One of the key structural features of the Demag Wheel Systems is its modular design. This allows for easy customization to meet specific requirements, whether for different wheel sizes, load capacities, or operating environments. The system includes a high-precision bearing assembly that ensures minimal friction, reducing energy consumption and wear. Low friction and high resistance wheel blocks are also equipped with shock absorption elements that minimize the impact of heavy loads, ensuring smoother operation and reducing strain on other mechanical components of the stacker. This design promotes a longer service life for the equipment and reduces maintenance costs, providing a more cost-effective solution in the long run.

The stability travel wheel within the DEMAG system plays a pivotal role in stabilizing the stacker during both movement and loading/unloading operations. These rigid design wheels are engineered to handle heavy, uneven, or irregular loads with ease, ensuring that the stacker remains steady during lifting and lowering processes. This stability is particularly crucial in environments where precision and safety are paramount. Whether the stacker is handling large containers in a port, moving construction materials in a warehouse, or transporting pallets across a distribution center, the travel wheels ensure smooth and controlled movement, reducing the risk of accidents or damage to goods.

In terms of application, the wheel blocking system is ideal for industries such as warehousing, logistics, shipping, and construction. It enhances the stacker’s ability to handle heavy-duty tasks, such as lifting large pallets, containers, or bulk materials, and moving them across long distances or over complex terrain. The robustness and versatility of the wheel block system make it well-suited for environments with demanding operational conditions, such as high load-bearing requirements, frequent use, or exposure to extreme weather. This ensures that the stacker can perform reliably in the toughest environments while maintaining optimal efficiency and safety standards.

In conclusion, the Quiet Stacker Wheel Block System is a state-of-the-art solution for improving the performance and longevity of material handling equipment. With its advanced structural features, durability, and versatile applications, the system is an essential component for industries that rely on heavy-duty stackers. By ensuring smooth, safe, and efficient movement of the stacker, the DRS system plays a crucial role in enhancing overall operational efficiency, reducing downtime, and increasing the productivity of material handling tasks. MAILUN POLYURETHANE produces and designs standard wheel blocks with a range of 112mm to 500mm. We can also customize wheel boxes with different materials, hardness, size, and load-bearing capacity according to industrial needs. If you have any needs, please feel free to contact us.