DRS Wheel Block System

DRS-112-A30-A-47-K-H-A10 Wheel Block System

The DRS-112-A30-A-47-K-H-A10 wheel block system delivers reliability, durability, and precision for stacker travel, automated warehouses, and heavy-load transport. It combines advanced engineering and customization to enhance efficiency.

The DRS-112-A30-A-47-K-H-A10 wheel block system delivers reliability, durability, and precision for stacker travel, automated warehouses, and heavy-load transport. It combines advanced engineering and customization to enhance efficiency.

When reliability, durability, and precision matter in material handling systems, the DRS-112-A30-A-47-K-H-A10 wheel block system is a cutting-edge solution. Designed for demanding industrial applications, this driven wheel block system combines advanced engineering with customizable features to optimize performance in stacker travel systems, automated warehouses, and heavy-load transport environments. Below, we delve into the details that make this system a standout choice for businesses seeking efficiency and longevity.

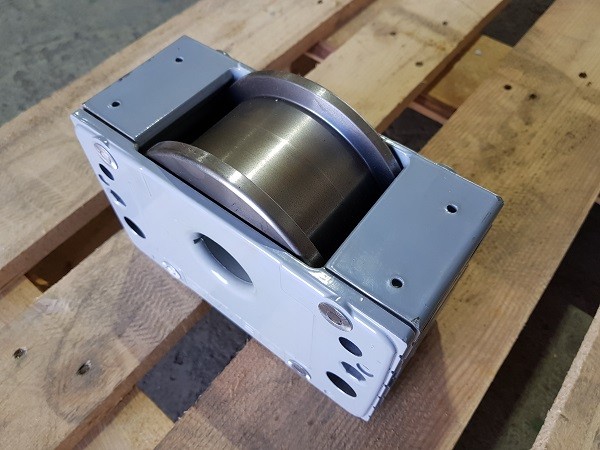

Unmatched durability with spheroidal graphite cast iron

The Demag DRS-112-A30-A-47-K-H-A10 wheel block system leverages spheroidal graphite cast iron (GJS/GGG) for its wheelset, a material renowned for its exceptional strength, wear resistance, and shock absorption. Unlike traditional cast iron, this advanced alloy minimizes cracking under high stress, ensuring extended service life even in environments with heavy cyclic loads. The dual-flange design on both sides of the wheel enhances lateral stability, preventing derailment and misalignment during operation.

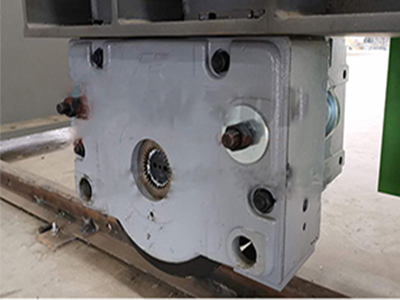

Enhanced stability with horizontal guide rollers

Standard horizontal guide rollers on the DRS-112-A30-A-47-K-H-A10 ensure optimal alignment during travel, minimizing lateral drift and reducing uneven wear on rails. This feature is critical for maintaining precision in automated systems, where even minor deviations can disrupt workflow.

Customizable to your needs

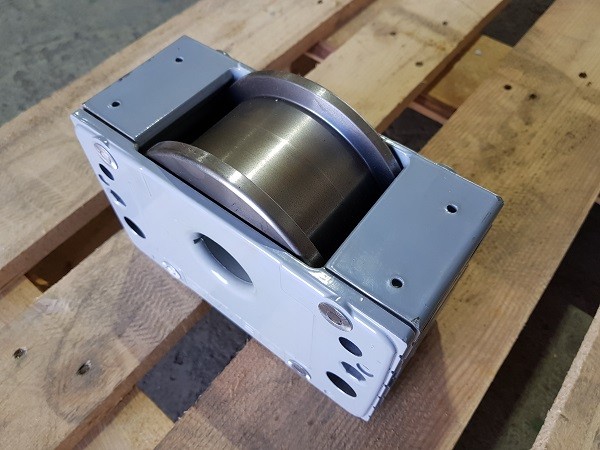

While the base model excels in performance, the DRS-112-A30-A-47-K-H-A10 wheel block system offers extensive customization. Tailor gear ratios, wheel coatings, load capacities, or connection types (top or side) to match specific operational demands. Whether you require adjustments for extreme temperatures, higher loads, or unique rail profiles, this system adapts to your requirements.

Why choose the DRS-112-A30-A-47-K-H-A10?

2.75 ton load capacity: Built to handle heavy-duty applications without compromising speed or safety.

Offset A10 gearboxes: Optimize torque delivery and energy efficiency.

Top connection design: Simplifies integration with existing machinery.

Long-term cost savings: Durable materials reduce replacement frequency and downtime.

Final thoughts

The DRS-112-A30-A-47-K-H-A10 wheel block system redefines reliability in material handling. From its robust spheroidal graphite cast iron construction to its noise-reducing polyurethane coating, every detail is engineered to enhance productivity and reduce operational costs.

Ready to upgrade your system?

Don’t settle for generic solutions. Contact our team today to discuss how the customizable Demag DRS-112-A30-A-47-K-H-A10 Wheel Block System can optimize your operations. Request a quote or consult our experts to tailor this system to your exact needs—because precision engineering should never be a compromise.