The Application of Polyurethane Coating in DRS Travelling Wheel Block

Polyurethane Coating Crafting

DRS wheel block is the casting type polyurethane travelling wheel block, which is made of liquid polyurethane rubber by casting method.Compared with ordinary roller, polyurethane travelling wheel block has high mechanical strength (2-3 times of natural rubber), excellent wear resistance, (5-10 times of natural rubber), outstanding compression resistance,and wide hardness range, which has high elasticity even under high hardness! (This is not the characteristics of other rollers)

In addition, the polyurethane travelling wheel block has high surface finish and superior machining performance! The adhesion with metal is also much higher than ordinary rubber, which is more suitable for a certain line speed and high pressure use!

Demag Travelling Wheel Block

Imported Demag travelling wheel block is expensive, Chinese domestic travelling wheel block is economical and practical, and the majority of lifting machinery commonly used accessories.

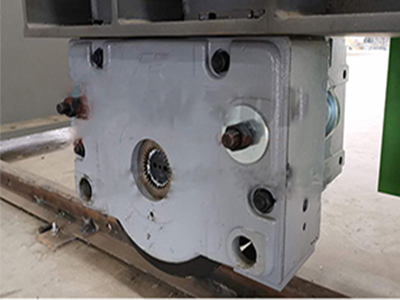

DRS travelling wheel has high tensile strength, surface high-frequency quenching, wear resistance, its design service life up to ten years. Demag travelling wheel is a key part of the crane walking mechanism, which is used to support the crane load on the track to make the crane repeatedly run the important equipment. DRS travelling wheel is mainly composed of wheels and shafts, bearings and bearing boxes, etc., and its quality has a great impact on the crane. Therefore, we must do a good job in the use of DRS wheel block safety operation requirements.

DRS travelling wheel block is a multi-purpose and compact travelling wheel block with a wide range of wheel loads ranging from 2.75 tonnes to 40 tonnes,which is simple and flexible to use with excellent performance. The scientific series division (DRS112 to DRS500) helps ensure that there is a matching DRS wheel case for every application. Demag wheel block as a key part of the crane travel mechanism, used to support the load of the crane on the track to make the crane repeatedly run the device. It is mainly composed of wheels and shafts, bearings and bearing boxes, etc., and its quality has a great impact on the crane.