6 years production experience

PRODUCT CENTER

The DRS wheel block system products available in our company with different models to meet the drive needs of various industries.

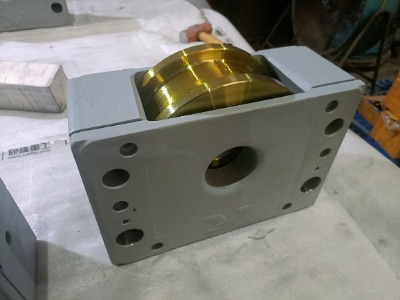

High Duty Demag DRS 400 Wheel Block With Single Flange

High rigidity Demag DRS 400 wheel block with single flange is used to support cranes and load devices that can bear a load of 30 t.

DRS 200 Wheel Block with Side Connection (W-Type) Mounting

Maximize your crane's hook height and structural stability with the Demag DRS 200 Wheel Block with Side Connection (W-Type).

DRS Wheel Block Shaft System for DRS‑M Series

DRS Wheel Block Shaft System — preassembled shafts for DRS 250–500 & DRS‑M series. 16–40t capacity, ±1mm precision, sealed bearings for low‑maintenance heavy travel.

High Load Capacity DRS Wheel Block in Automated Systems

Among the critical components enabling seamless material handling is the automatic handling drive travel wheel block—a robust solution designed to optimize the movement of goods in automated systems.

Wheel Block System for Heavy-Duty RGV

High-performance RGV Demag wheel block system replacements for heavy-duty automated logistics—superior load capacity, precision, durability, and cost-efficiency for your RGV operations.

DRS Drive Wheel Block for Demag Cranes

Demag Crane DRS Wheel Block: GGG ductile iron housing, GGG70 wheel (HRC50+), sealed bearing & modular design for heavy-load, corrosion-resistant crane operations

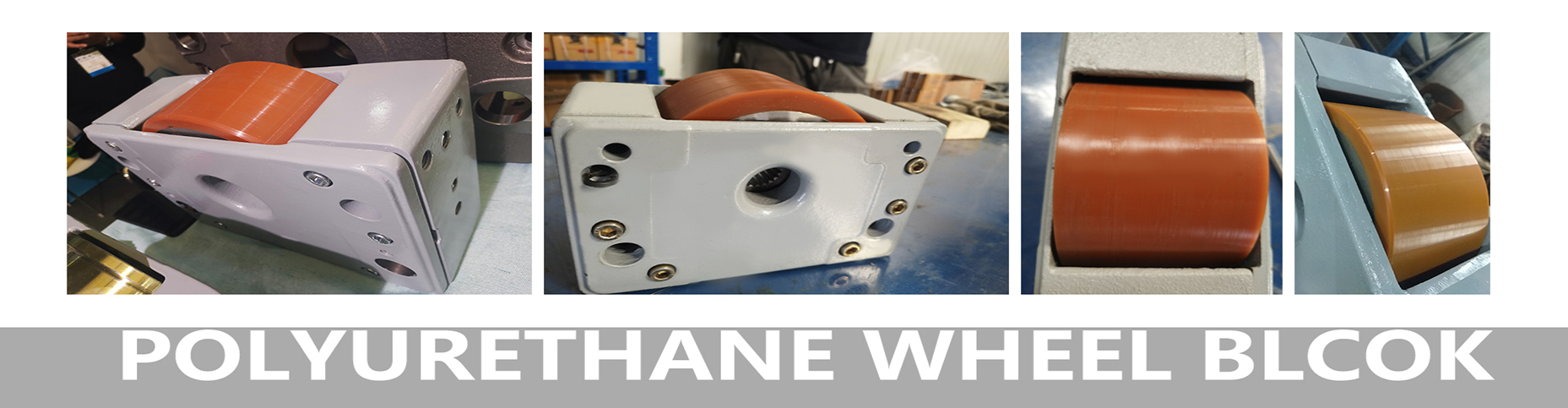

DRS 315 Wheel System & Polyurethane Wheels for Stacker Cranes

Optimize stacker crane performance with the DRS 315 wheel system and high-traction polyurethane wheels for enhanced precision, reduced noise, and lower maintenance.

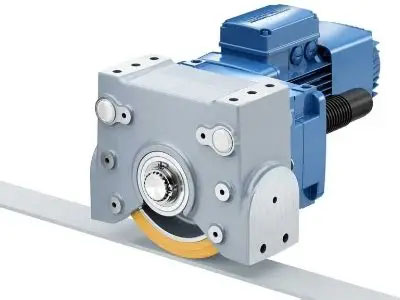

SEW Drive Solutions for Demag DRS Wheel Systems

Discover SEW RS/DRE/DRP series motors with DRS wheel block systems. This powerful combination enhances performance, achieves IE1 to IE4 energy efficiency, and handles load capacities from 2.75 to 40 tons for superior material handling solutions.

DRS Flangeless Wheel Block for Demanding Material Handling

The DRS Rimless Travel Wheel Block is a compact and modular wheel system designed for a wide range of material handling and transportation applications. Unlike conventional wheel blocks with flanges or rims, the rimless design allows for greater flexibility in layout, reduced installation constraints, and enhanced operational smoothness.

Industrial Heavy-Duty Double-Flange Travel Wheel Block

The DRS double-rim travel wheel block system is a robust and versatile solution designed for industrial applications requiring precise movement, high load capacity, and reliable performance.

DRS 400 Wheel Block Systems

In the field of industrial lifting and material handling, the DRS400-NA30-B47-K-H-A10 wheel block system represents a top-tier rolling solution, delivering exceptional precision, reliability, and operational efficiency.

DRS 250 Wheel Blocks for Heavy-Duty Applications

Heavy-duty wheel block solution for applications in steel, energy, and logistics. DEMAG 250 wheel system delivers precision positioning, extended service life, and optimal TCO for critical operations.

DRS 160 Wheel Block System High Performance Crane Travel Solution

The DEMAG DRS 160 wheel Block Systemis a high-performance, modular core component of crane travel mechanisms. It is renowned for its exceptional reliability, high load capacity, and flexible configura

DRS 125 Maintenance for Longer Crane System Life

Learn expert tips to extend the service life of Demag DRS 125 crane travel wheel blocks and maximize your ROI through proper installation, maintenance, and OEM support.

SEW RS/DRE/DRP Series Motor

SEW RS/DRE/DRP series motors are renowned for their versatility and efficiency in various industrial applications. When integrated into Demag's travel wheel systems, these motors enhance the performance and reliability of material handling equipment.

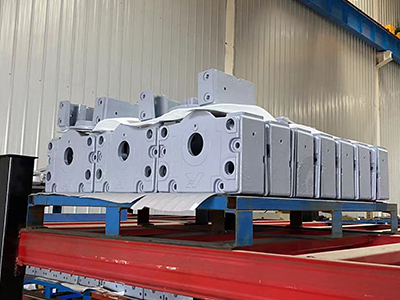

Case

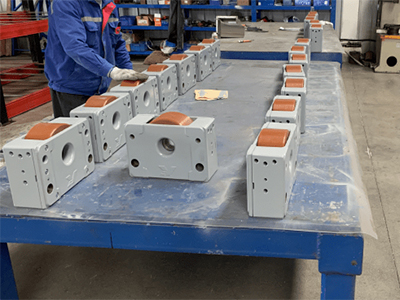

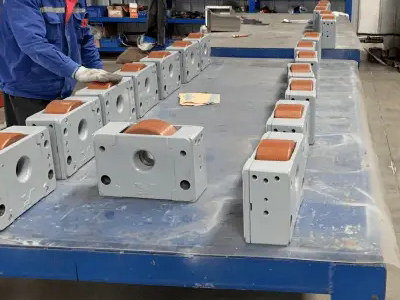

The DRS wheel blocks we produce are exported to numerous numerous countries globally, involving many industries, such as stacker wheels, AGV trolley wheels, crane wheels and customized wheels.

Case

Case DRS 160 Wheel Block in Siberia

DRS 160 Wheel Block System transformed a 32-ton crane in Novosibirsk, Russia. See how we overcame -40°C extreme cold and high dust challenges to eliminate rail wear and reduce energy consumption by 15%.

Case

Case 40-Ton RGV Traveling Wheel Block

Mailun Polyurethane, a leading wheel manufacturer in China, proudly presents the Rail Guided Vehicle (RGV) Traveling Wheel Block. Engineered to the highest standards, our wheel block system is designed

Case

Case DRS 315 Wheel Block for Demag Overhead Cranes in Thai

Eliminate frequent crane downtime and wheel flange wear. This case study details how replacing OEM wheels with the DRS 315 System improved efficiency for a major automotive manufacturer, extending maintenance intervals from 1 to 6 months.

Corporate cooperative customer

Production team/people

Factory area/square meter

Annual production volume/piece

News

MAILUN POLYURETHANE is a professional manufacturer of DRS wheel block systems. We provide our customers with comprehensive knowledge of industry news.

12

2025-12

- hits 511 +