How to Install Warehouse Travel Wheel Blocks

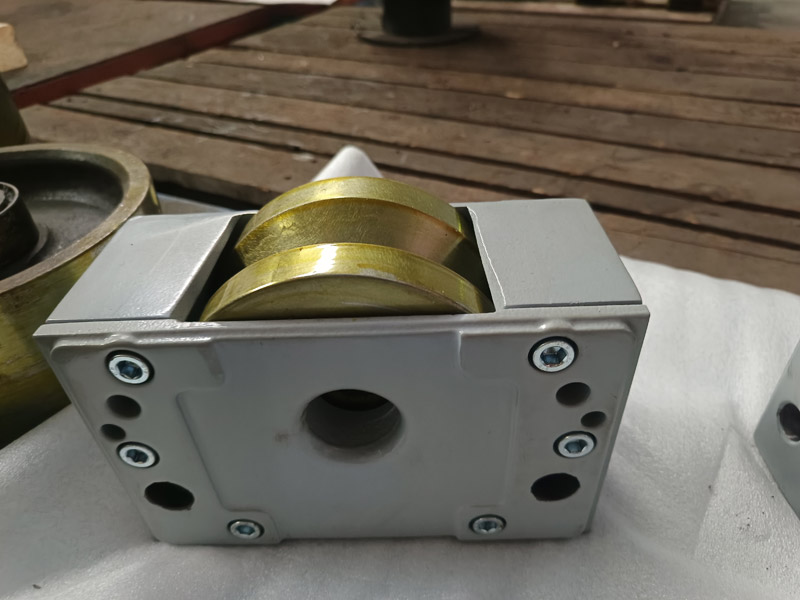

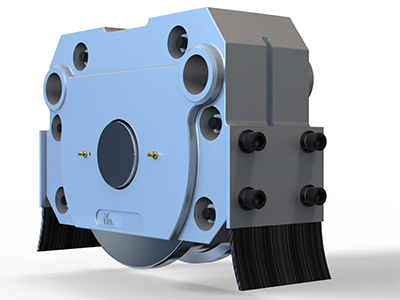

In warehouse operations, the travel wheel block is a critical component that ensures the smooth and efficient movement of heavy-duty equipment, including cranes, conveyors, automated guided vehicles (AGVs), and storage/retrieval systems. It functions as the primary support mechanism, enabling these systems to move accurately and reliably along fixed tracks or rails. The modular design of modern wheel blocks allows for even load distribution, reduced friction between moving parts, and enhanced operational stability.

By minimizing friction, high-quality travel wheel blocks help prevent premature wear on both the wheels and the rail surfaces, thereby extending equipment service life and reducing maintenance requirements. Furthermore, a well-engineered and correctly installed wheel block contributes to safe and efficient load handling, decreasing the likelihood of equipment failure or accidents that could disrupt operations or pose safety risks. In high-activity zones such as loading docks and narrow aisle systems, reliable wheel block performance is essential to maintaining continuous workflow and maximizing overall warehouse productivity.

Installation Method

Proper installation of a wheel block is vital to ensure its efficiency and durability under operational loads. The process can be divided into the following key steps:

Preparation

Before installation, the track or rail must be thoroughly cleaned and inspected for any damage or obstructions. The site should also be evaluated to confirm it meets load-bearing requirements and environmental conditions, such as temperature fluctuations, humidity levels, and potential vibrations.Positioning and Alignment

The wheel block is carefully placed onto the track, ensuring perfect alignment with the guiding rail. Precision is crucial at this stage—misalignment can lead to uneven wear and early system failure. Laser alignment tools are often used to achieve the required accuracy.Securing the Wheel Block

The assembly is fastened to the machinery or support structure using bolts, screws, or welding, depending on the design. Certain wheel blocks allow fine adjustments in height or angle via bolted connections, making them adaptable to specific operational demands such as variable loads or track profiles.Testing and Adjustment

After installation, the system should be tested under controlled conditions. This includes checking for smooth wheel movement, abnormal noise, vibration, or excessive friction. Necessary adjustments are made to optimize alignment and performance.Maintenance and Lubrication

Regular maintenance and lubrication of the wheel block and its bearings are essential to ensure long-term functionality. Proper lubrication reduces wear, prevents corrosion, and enhances the service life of both the wheel block and the track.

In summary, the travel wheel block is an indispensable element in warehouse automation, providing essential support, load distribution, and mobility for material handling systems. Correct installation, precise alignment, and consistent maintenance are key to achieving operational efficiency, safety, and durability. MAILUN specializes in the custom manufacturing of wheel blocks tailored to specific size, material, and installation requirements. Should you have any inquiries or project needs, please feel free to contact us—we look forward to collaborating with you.