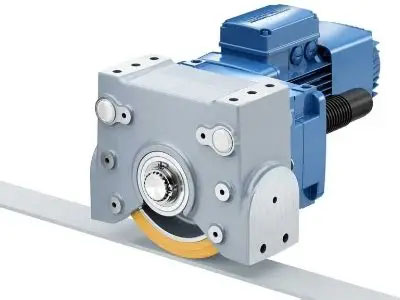

The Industrial Application of Demag Travelling Wheel Block

With the rapid development of industrial technology, DRS travelling wheel blocks are widely used in various industrial equipment. It not only provides stable mobility for the equipment, but also ensures efficient and safe operation of the equipment on the production line. Demag travelling wheel can be divided into DRS 112-DRS 500, the DRS 500 is used for heavy handling generally. However, in order to ensure the best performance of DRS travelling wheel blocks in industrial environments, the following points must be fully considered.

Choose The Right Materials

The material choice of DRS travelling wheel block is very important. Considering the corrosion, high temperature, heavy load and other factors in the industrial environment, materials with high strength, wear resistance, corrosion resistance and other characteristics should be selected. For example, materials such as stainless steel and high-strength alloys ensure that the wheel case will maintain good performance in harsh environments.

Accurate Design and Manufacturing

The design of the wheel block must be precise to every detail. This includes wheel diameter, width, material thickness, bearing selection, etc. The precise design ensures the stability and durability of the wheel block in operation. At the same time, quality control in the manufacturing process is also indispensable, and any small flaw may become a hidden danger of equipment failure.

Adaptability and Flexibility

Due to the diversity and complexity of industrial equipment, DRS travelling wheel blocks need to have a certain degree of adaptability and flexibility. This means that the wheel block needs to be able to cope with different working environments and work needs, such as different ground conditions, temperature changes, load changes, etc. Therefore, when designing and selecting the wheel box, its adaptability in practical applications must be fully considered.

Maintenance

Even the highest quality DRS walking wheel blocks will gradually deteriorate in performance if they are not properly maintained and maintained. Therefore, it is essential to establish a regular maintenance and maintenance schedule. This includes cleaning, lubrication, fastening loose parts, etc. Through timely maintenance and maintenance, you can ensure that the wheel block is always in the best working condition.

Security Considerations

In an industrial environment, safety is always the primary concern. DRS travelling wheel blocks must be designed and manufactured to meet relevant safety standards and regulations. In addition, in the process of use, it is necessary to ensure the safety training of the operator to avoid accidents caused by improper operation.

In summary, the application of DRS travelling wheel blocks in industrial equipment requires comprehensive consideration of material selection, design and manufacturing, adaptability and flexibility, maintenance and maintenance and safety and other aspects of the key points. Only in this way can we ensure the stable operation of the wheel block in the industrial environment and provide a strong guarantee for the production efficiency and product quality of the enterprise.